Food labelling is essential in any food retail operation End of line packaging automation in pakistan, as it helps to ensure food safety while also providing nutritional information to customers and customers’ families. Recent years have seen an increase in the amount of regulation placed on food labelling to assist purchasers in determining if an item satisfies their dietary requirements. As a result, quality inspectors have difficulty evaluating labels that include a lot of information. In this essay, we will cover the advantages of visual inspection systems as well as the reasons why food companies should implement them immediately End of line packaging automation in pakisatn.

Reviewing and evaluating labels and printing

The information on labels and films must be accurate and readable in order to comply with legislative requirements for consumer information and traceability. Because of corporate requirements, food labelling is becoming increasingly complex.

At accordance with the European Union Food Information Regulation, all mandatory information must be print in a minimum size. It is necessary to include the best-before date, allergy information, and a consumer-friendly nutritional table in a clearly defined format, among other things. Another type of data is batch numbers, which are use for traceability, as well as different emblems and approval stamps, barcodes for scanners, and QR codes

The growing number of product categories, as well as the requirement for information on labels to be available in a variety of languages, contribute to the challenge.

In parallel with the increasing complexity of food labelling, manufacturers, particularly exporters, are coming under increasing pressure to increase their output. Returns may occur as a result of labelling difficulties such as illegible barcodes, incorrect use-by dates, or simply using the incorrect product label on the package. Manufacturers are subject to significant direct and indirect expenditures, which range from transportation and disposal to replacement manufacturing and brand reputational damage.

Serious breaches may result in contractual fines or the removal of a product from the market. Cosmetic flaws, such as a misaligned label, can impair a brand’s reputation by leading consumers to believe that the product is of poor quality and that the company was negligent in its processing and packaging.

Quality control should be perform early in the production cycle

Even if labelling issues found during the manufacturing process End of line packaging automation in pakistan , they could result in significant financial losses. Up to the point of secondary packaging, the process is routinely mechanised. A defect detected during a random check at the conclusion of a batch may render it worthless or necessitate the need for extensive reprocessing and repackaging of the batch. Quality checks should be conduct as early as possible in the process to ensure that the process runs smoothly.

In order to ensure that only faultless packets enter the retail chain, individual pack quality control must be carrier out. Random checks in industrial manufacturing and packaging operations are no longer sufficient to provide 100 percent security in these processes. It is no longer possible to perform full label verification with the human eye because of the increased output capabilities of packaging lines as a result of automation. As a result, high-cycle food companies must rely on automated inspection systems to ensure product quality.

Multivac has a wide range of products to assist you

Multivac provides a wide range of label inspection solutions, ranging from the most basic to the most complex.

Checking for print and variable integrity, as well as code legibility, are all common uses for this library. OCR and character verification (OCV) are among the more complicated jobs that inspection systems may perform, as is code analysis, and pattern recognition for analysing logos or prescribed label shapes, among other things. They ensure that each individual pack is thoroughly tested to verify that it meets your criteria, even when working at fast rates.

Sensors that detect the presence of labels include luminescence, colour, and contrast sensors. Barcode scanners and code readers, on the other hand, can check for labels and the legibility of barcodes. It is possible to compare the content of the code to the reference data.

For sophisticated or multipurpose inspection jobs such as character and pattern recognition. PC-based matrix or line scanner systems, such. As the Multivac MVS, are the preferred equipment. The Multivac I 420 inspection solution. For a thermoforming packing machine employs character recognition. Or character verification to check the legibility. Of pack marks and the code content contained inside them. Detection of all label position and alignment elements is possible. The usage of an optical character recognition (OCR) technology to analyse prints means. That Multivac can also give a “OCR specification.” In order to ensure that the labels can read flawlessly by the inspection system. And as a result, validated 100 percent reliably, this standard specifies the typefaces. Line spacing, contrast, and other necessary qualities that must be present.

For efficiency to be achieve, a faultless connection is require

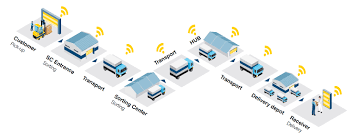

It is possible to install the inspection system on either the outfeed. Or on the infeed of a packing machine, depending on the requirements of the application. Visual inspection systems can be integrate into conveyor belt labellers or used. As a stand-alone solution after a traysealer to ensure that. The product is properly labelled. Many existing packaging lines can be simply retrofitted. With inspection equipment, saving time and money.

Each and every one of Multivac’s inspection systems may be fully integrated. Into the human-machine interface (HMI) of the thermoform packaging machine or labeler. The Multivac HMI is also used in stand-alone applications. The upshot is that the operator of a packaging line may operate. All of the components using a single operating system. Hence lowering setup times and error rates. The ideal situation is for all line modules to be controller from a single control terminal. This enables for complete line integration. With all settings for all modules being save and promptly loaded with the recipe. Reducing product changeover times.

Integrated line control has a number of advantages as well. An inline quality inspection system can assist in the ejection of reject packs. And even the changing of module configurations. While the packaging process is still in progress. If a print image or label is progressively deteriorating, countermeasures. Can be implement to prevent the problem from becoming worse. Before the print image or label exceeds the acceptable tolerance range. As a result, reject packs can be identifier early on and avoided.

Multivac has a wealth of knowledge industradgroup. And experience in the field of visual inspection systems. And the smooth integration of these systems into packaging operations. As a result of Multivac’s considerable knowledge. The company can provide thorough advise and tailor solutions. To meet the individual requirements of each customer. An automated visual inspection system. Provides value and security in every part of its operation. And the investment is often recovered within a short period of time.